High viscosity pump technology plays a crucial role in industrial operations across mining, oil and gas, municipal wastewater, and manufacturing, where fluids are often far more challenging to handle than water. These include sludges, heavy oils, adhesives, and slurries, substances that resist flow and place significant strain on pumping systems. To manage them effectively, engineers and procurement professionals depend on pumps designed specifically to move dense, sticky, or abrasive fluids without compromising efficiency or reliability.

Not all motors are designed for this purpose. Centrifugal pumps remain the most widely used design in the industry due to their ability to move large volumes of low-viscosity liquids, such as water and mild chemicals. However, their efficiency gradually decreases as viscosity increases. Positive displacement pumps, such as screw, gear, progressive cavity, or lobe types, are designed to provide a consistent flow regardless of fluid thickness. This makes them the obvious choice when specifying a pump for high viscosity pumps in challenging conditions.

This blog will examine seven industries where the right pumping technology has a direct impact on operational efficiency, lifecycle costs, and regulatory compliance. From mining tailings to municipal sludge handling and chemical transfer, the applications show how selecting the right high viscosity pump safeguards uptime, protects assets, and ensures a measurable return on investment.

Understanding High Viscosity Pumps

High-viscosity fluids, such as sludge, crude oils, thick pastes, and mineral slurries, present unique challenges in industrial operations. These materials resist flow, require more energy to move, and can quickly wear down equipment that isn’t designed to handle them. For procurement heads and project managers, the ability to specify the right pump for high viscosity pumps is important to ensure process reliability, reduce downtime, and control operating costs.

Unlike standard centrifugal models, which lose efficiency as fluid thickness increases, high viscosity pump types are engineered to maintain consistent performance regardless of the fluid’s density. They achieve this by moving fixed volumes of fluid with each cycle, delivering steady flow and preventing the shearing that can compromise product integrity or damage sensitive materials. Selecting the right pump for high viscosity pumps ensures that operations remain both technically sound and economically viable.

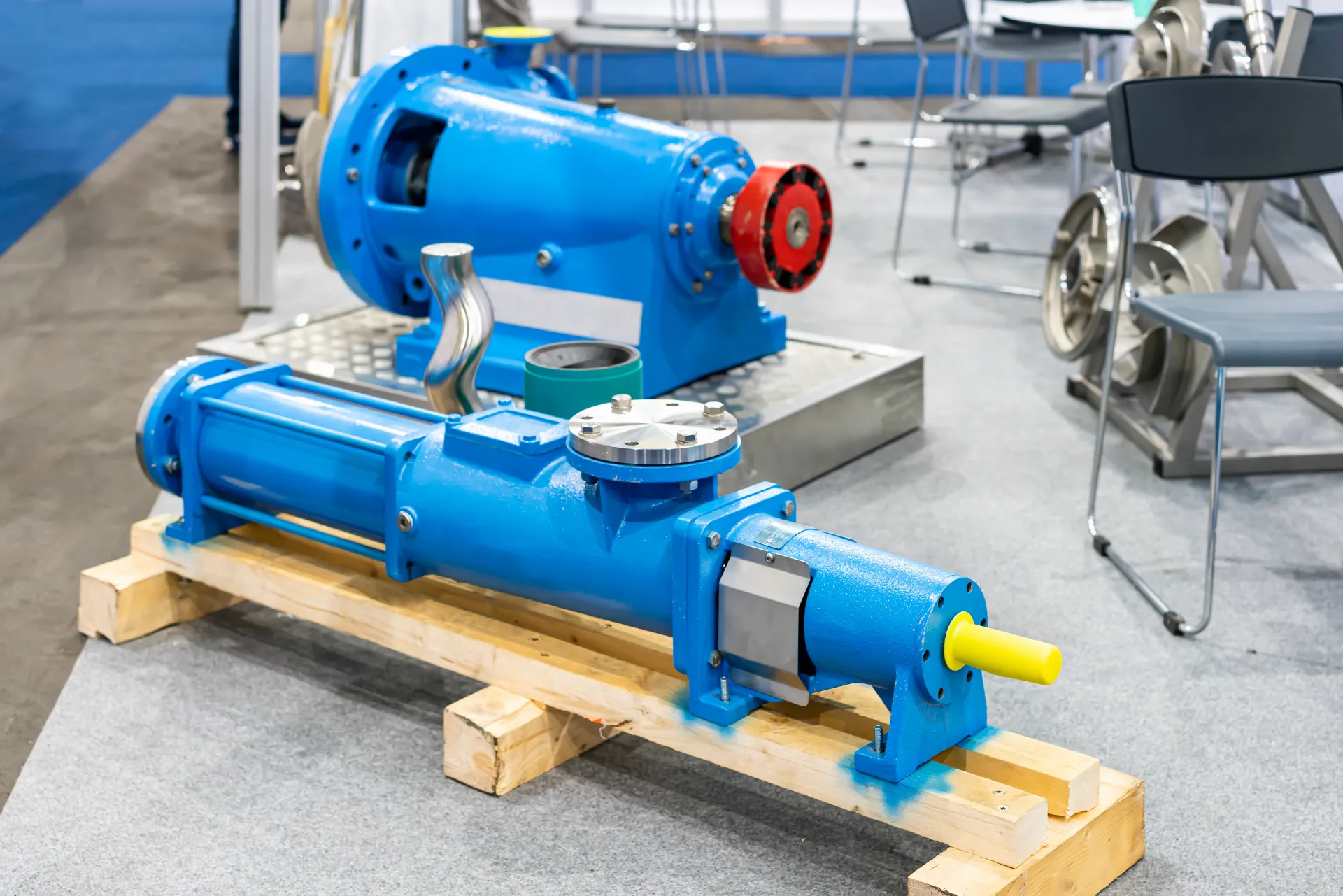

Several high viscosity pump types serve different industrial applications:

- Progressive cavity pumps: for sludge, slurry, and wastewater treatment.

- Screw pumps: ideal for petroleum products and heavy oils.

- Gear pumps are suitable for lubricants, fuels, and viscous chemicals.

- Lobe pumps are suited to food and beverage applications that require hygienic transfer.

- Diaphragm pumps: for abrasive or corrosive fluids.

- Peristaltic pumps: for precise metering of pastes and chemical solutions.

Each of these high viscosity pump types is selected not only for compatibility with fluid properties but also for its ability to reduce energy consumption and extend equipment life. For contractors and industrial decision-makers, investing in the right pump for high viscosity pumps translates directly into lower maintenance budgets and improved long-term return on investment.

By understanding the range of available high viscosity pump types and matching them with the unique demands of specific projects, stakeholders can optimize performance while meeting strict operational and compliance standards. Whether in mining, oil and gas, or municipal projects, the right high viscosity pump type is the foundation for efficiency and reliability.

Industry Applications

Oil & Gas

The oil and gas industry is one of the largest users of specialized pumping equipment, as it must transport crude oil, drilling mud, and bitumen, fluids that range from moderately thick to extremely viscous. Standard centrifugal designs cannot maintain efficiency in these conditions, which is why operators rely on pumps engineered to handle high viscosity, designed to handle fluctuating densities, and abrasive content. On offshore rigs, screw and gear pumps are two widely adopted high viscosity pump types that enable the stable transfer of fluids in environments where viscosity changes drastically with temperature.

Beyond flow reliability, the safety implications are important. An unorganised matched pump can cause leaks, equipment failures, or environmental disasters. By selecting the right pump for high viscosity applications, project managers and procurement experts ensure regulatory compliance, improve worker safety, and minimize costly downtime. With 24/7 refinery operations, high viscosity pump types also reduce energy consumption and extend equipment life, protecting budgets in industries where every hour of downtime incurs significant financial penalties.

Mining & Mineral Processing

Mining environments demand rugged, abrasion-resistant equipment to move thick slurries, tailings, and mineral pastes. A high viscosity pump ensures that dense materials are transported efficiently from processing plants to disposal or recovery areas without clogging or premature wear. Progressive cavity and diaphragm designs, both proven high viscosity pump types, are favored for their ability to handle abrasive solids while maintaining reliable output.

For leaders and project managers, the benefits extend to measurable ROI. Every unplanned stoppage in slurry or tailings transport translates into production losses. By specifying high viscosity pump types with wear-resistant components, operators can reduce downtime, extend service intervals, and avoid costly emergency repairs. In large-scale mines, this not only boosts throughput but also ensures compliance with environmental regulations on waste handling, making the high viscosity pump an operational necessity rather than an optional investment.

Chemical & Petrochemical Industry

Chemical plants work with a diverse range of viscous substances, including adhesives, polymers, resins, and industrial chemicals. Many of these fluids are shear-sensitive, meaning they can degrade or lose quality if moved with the wrong equipment. High viscosity pump types, such as gear and peristaltic pumps, deliver the controlled transfer needed to protect chemical integrity.

Accuracy is also paramount. In processes where even minor deviations can lead to quality failures, a high viscosity pump ensures precise metering, mixing, and transfer. This precision helps chemical manufacturers minimize product waste, maintain batch consistency, and comply with stringent safety regulations. By relying on high viscosity pump types designed for corrosive or high-temperature fluids, project managers reduce risk exposure, protect system assets, and achieve longer equipment lifecycles in one of the world’s most compliance-driven sectors.

Food & Beverage Processing

In food and beverage operations, viscosity challenges arise from products such as chocolate, syrups, fruit concentrates, and dairy-based pastes. These products require equipment that strikes a balance between efficiency, hygiene, and gentle handling. High viscosity pump types, such as lobe and peristaltic pumps, are designed to move these materials without damaging their texture or composition.

Sanitation is equally important. A pump for high viscosity pumps in this industry must support clean-in-place (CIP) or sterilize-in-place (SIP) procedures to meet health and safety standards. By choosing the right design, processors achieve smoother transfers, reduced waste, and higher throughput without compromising product quality. For procurement teams, high viscosity types represent more than just a technical solution—they ensure compliance with food safety laws, extend production capacity, and help deliver consistent consumer products at scale.

Water & Wastewater / Municipal Sector

Municipal treatment plants face one of the toughest challenges in fluid handling: moving thick sludge, biosolids, and concentrated waste. A pump for high viscosity pumps provides the continuous reliability needed to keep these facilities operating within regulatory limits. Progressive cavity and diaphragm pumps, proven high viscosity pump types, ensure that sludge transfer and dewatering processes are managed with maximum efficiency.

For government buyers, the economic impact is clear. Poorly selected equipment increases energy use, requires more operator intervention, and accelerates wear. By specifying high viscosity pump types designed for sludge applications, municipalities can cut operational and maintenance costs while improving compliance with environmental discharge standards. A reliable pump for high viscosity pumps not only protects budgets but also safeguards critical public infrastructure.

Construction & Infrastructure

From tunneling to large-scale concrete work, construction projects often involve viscous materials, including grout, sealants, and concrete admixtures. Contractors rely on a pump for high viscosity pumps to maintain flow rates in environments where temperature, site conditions, and material thickness can fluctuate daily. High viscosity pump types, such as screw and progressive cavity pumps, are known for delivering consistent pressure and reducing manual labor requirements.

The benefits extend directly to project ROI. Reliable pumping reduces the risk of stoppages, rework, and wasted material, factors that can derail tight construction schedules. For procurement heads overseeing large projects, specifying high viscosity pump types translates into reduced labor costs, tighter quality control, and faster project delivery, making the right pump for high viscosity pumps a competitive advantage.

Marine & Naval / Defense Applications

Marine and defense operations must deal with fluids such as ballast sludge, bilge waste, and heavy fuel oils, all of which demand durable equipment. A high viscosity pump materials ensure that vessels and port facilities handle these materials safely, efficiently, and in compliance with international maritime regulations. High viscosity pump types, such as screw and gear pumps, are favored in naval and port applications due to their ability to operate reliably in corrosive, saltwater-influenced conditions.

Government buyers place particular emphasis on lifecycle costs. The correct pump for high viscosity pumps minimizes failures, reduces maintenance intervals, and ensures compliance with defense and marine standards. For naval fleets, high viscosity pump types provide the reliability needed to maintain operational readiness in critical missions, while commercial ports benefit from increased uptime and reduced environmental risk.

Key Considerations When Selecting a Pump for High Viscosity Applications

Choosing the right pump for viscous fluids involves more than just capacity ratings; it requires a careful match between the pump design, fluid properties, and long-term operational goals. For procurement heads, project contractors, and government buyers, three factors consistently influence the successful procurement of high viscosity pump types:

Matching Pump Type to Fluid Properties

Every fluid has distinct characteristics that affect pump performance, including temperature sensitivity, abrasiveness, and chemical composition. For example, heated bitumen requires equipment that maintains flow at varying viscosities, while abrasive mining slurries demand wear-resistant designs. Specifying high viscosity pump types, such as screw, gear, or progressive cavity models, ensures that pumps are aligned with these properties, thereby reducing mechanical stress and improving efficiency.

Balancing Energy Consumption with Flow Reliability

Viscous fluids require more energy to move, making efficiency a critical concern. Centrifugal pumps often waste power under these conditions, whereas positive displacement designs maintain a steady output regardless of the thickness. Decision-makers should evaluate how each pump for high viscosity pumps balances energy consumption against flow stability.

The most effective pump for high viscosity pumps optimizes both, lowering operating expenses while delivering uninterrupted performance.

Weighing Maintenance and Lifecycle Costs Against Purchase Price

While initial cost is a factor, the long-term financial impact of downtime, spare parts, and labor often outweighs upfront savings. A rightly chosen pump for high viscosity fluids extends service life, minimizes failures, and ensures easier maintenance access. By comparing lifecycle costs to purchase prices, buyers can justify investing in durable, high viscosity pump types that provide predictable ROI and reduce the total cost of ownership over time.

Conclusion

High viscosity pumps play a crucial and positive role in various industries, including oil and gas, mining, chemicals, food processing, municipal wastewater treatment, construction, and marine applications. These industries rely on specialized pumping technology to transport difficult fluids, including crude oil, slurries, adhesives, syrups, and sludge, which regular centrifugal pumps cannot handle successfully.

By applying the right pump technology, decision-makers gain measurable advantages: steady flow rates, compliance with safety and environmental standards, lower maintenance requirements, and predictable ROI. Whether it is reducing downtime in a mine, safeguarding quality in a food plant, or ensuring operational readiness in naval applications, the right pump selection directly impacts efficiency and long-term cost savings.

Pump and Dredge Solutions understands the technical and budgetary pressures that procurement managers, contractors, and government buyers encounter when specifying equipment. Our team of experts provides specialized recommendations for a wide range of high viscosity pump types solutions, ensuring that each project achieves maximum performance and reliability.

Contact us today to discuss your project requirements and discover the most effective pump solutions for your operations.