I. Introduction

Regular maintenance is crucial for the optimal performance and longevity of pump and dredge equipment. These machines are the backbone of many industrial operations, from construction to mining, and their efficiency directly impacts productivity and costs. Proper maintenance practices not only extend the lifespan of the equipment but also ensure that it operates at peak performance, reducing the likelihood of costly breakdowns and downtime. The purpose of this blog is to provide essential maintenance processes that will keep your pump and dredge gear running efficiently and reliably.

II. Understanding the Basics of Pump and Dredge Equipment Maintenance

A. The Role of Regular Maintenance

Regular maintenance is the key to preventing unexpected breakdowns and extending the life of your pump and dredge gear. When maintenance practices are followed on a routine basis, potential issues can be identified and addressed before they escalate into major problems. This proactive approach minimizes downtime, which is critical for maintaining operational efficiency. Furthermore, consistent maintenance helps keep the equipment running smoothly, ensuring that it performs optimally in demanding environments.

B. Key Components That Require Regular Attention

Certain components of pump and dredge equipment are particularly susceptible to wear and tear and require regular attention. For pump equipment, these components include impellers, seals, hoses, and engines. Impellers must be inspected for wear, as their efficiency can degrade over time. Seals and gaskets are also critical; if they fail, leaks can occur, leading to operational inefficiencies or even damage to the pump equipment. Hoses need to be checked for cracks and blockages that could impede fluid flow. Engines, being the powerhouse of the equipment, should be regularly serviced to ensure they are functioning properly.

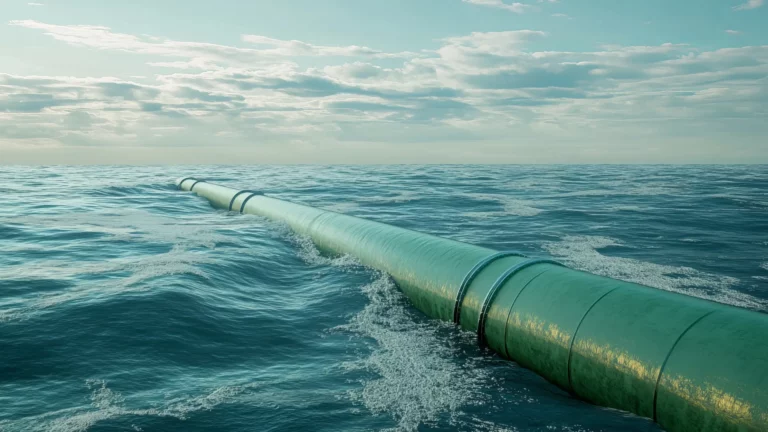

Key components in dredge machinery include cutter teeth, hydraulic systems, and pipelines. Cutter teeth wear down when used and must be replaced to maintain dredging efficiency. Hydraulic systems are vital for the operation of dredge machinery, and any leaks or malfunctions can lead to significant performance issues. Pipelines, which transport the dredged material, must be kept clear of blockages to ensure continuous operation.

III. Essential Maintenance Practices for Pump Equipment

A. Regular Inspection and Cleaning

Routine inspections are essential for identifying signs of wear and tear on pump equipment. Regular checks allow operators to spot potential problems early, such as corrosion, blockages, or damaged components. Cleaning is equally important, as debris and sediment can accumulate and cause blockages, reducing the efficiency of the pump equipment and potentially leading to more severe issues like overheating or mechanical failure. Implementing thorough maintenance processes like these ensures that your pump equipment remains reliable and effective.

B. Lubrication of Moving Parts

Lubrication is critical to reducing friction in moving parts, which helps prevent wear and tear. It’s important to follow best practices for lubricating pumps, including using the appropriate lubricant for the specific pump type. Different pumps may require different types of lubrication, and using the wrong one can lead to inefficiencies or damage. Regular lubrication as part of your maintenance practices ensures that the pump equipment operates smoothly and extends its lifespan.

C. Monitoring and Replacing Seals and Gaskets

Seals and gaskets are vital for preventing leaks and maintaining the efficiency of the pump. Over time, these components can wear out, leading to leaks that reduce the pump’s efficiency and can cause damage. It’s important to monitor these parts regularly for signs of wear, such as cracks or loss of elasticity, and to replace them as needed to prevent operational issues. Effective maintenance processes in monitoring and replacing these components are key to the longevity of your pump.

D. Motor and Electrical System Maintenance

The motor is the heart of the pump, and its performance must be consistently monitored. Regularly check the motor for any unusual noises, vibrations, or signs of wear. Electrical connections should also be inspected to ensure they are secure and free from corrosion. Proper maintenance practices of the motor and electrical system help avoid power issues and ensure the pump operates reliably.

IV. Essential Maintenance Practices for Dredge Equipment

A. Inspection and Replacement of Dredge Cutter Teeth

Cutter teeth on dredge machinery are subject to heavy wear and must be regularly inspected. Worn or damaged cutter teeth can reduce the efficiency of dredging operations, leading to longer project times and increased costs. Replacing cutter teeth as soon as they show signs of significant wear ensures that the dredge operates at peak efficiency. Incorporating this into your maintenance practices is crucial for the optimal performance of your dredge tool.

B. Maintaining Hydraulic Systems

Hydraulic systems are crucial for the operation of dredge machinery. Regular inspection of hydraulic lines and components is necessary to identify and address any leaks or malfunctions. Proper maintenance of hydraulic systems includes checking fluid levels, replacing filters, and ensuring that all connections are secure. By maintaining the hydraulic system through diligent maintenance practices, you can prevent performance issues and avoid costly repairs.

C. Dredge Pipeline Maintenance

Pipelines are an integral part of dredge equipment, transporting the dredged material from the site to a disposal area. Regular checks of the pipeline’s integrity are essential to prevent leaks and blockages. Cleaning and replacing sections of the pipeline as needed ensures a consistent flow of material, which is critical for maintaining productivity. Effective pipeline maintenance practices are key to the successful operation of dredge machinery.

D. Monitoring and Adjusting Dredge Pump Performance

The performance of the dredge pump should be regularly assessed to ensure it is operating efficiently. This includes monitoring the pump’s output and making any necessary adjustments to maintain optimal performance. Regular calibration of the pump is important to ensure that it continues to meet the demands of the dredging operation. Incorporating these maintenance practices into your routine ensures that your dredge tool remains in top working condition.

V. Developing a Maintenance Schedule

A. Importance of a Structured Maintenance Schedule

A well-organized maintenance schedule is essential for preventing costly downtime. By scheduling regular maintenance activities, you can ensure that all components of the pump and dredge equipment are properly cared for. This approach helps balance routine maintenance with operational demands, ensuring that equipment is available when needed and that maintenance does not interfere with productivity. Structuring your maintenance practices within a schedule ensures consistent and effective care of your equipment.

B. Customizing Maintenance Schedules Based on Equipment Usage

The frequency of maintenance should be tailored to the intensity of equipment use. More frequent maintenance may be required to keep heavily used equipment running smoothly. Conversely, equipment that is used less often may not need as much attention. Example schedules can be developed for both heavily used and occasionally used equipment, ensuring that each piece of equipment receives the care it needs based on its usage patterns. Customizing your maintenance practices in this way helps maximize the efficiency and lifespan of your pump and dredge equipment.

C. Using Maintenance Logs for Tracking

Keeping detailed maintenance logs is a best practice that allows you to track the history of each piece of equipment. These logs can help predict future maintenance needs and prevent unexpected failures by providing a record of past maintenance activities. By analyzing this data, you can make informed decisions about when to perform maintenance and what areas to focus on. Implementing maintenance practices that include thorough record-keeping helps ensure that your pump and dredge equipment remains in excellent condition.

VI. Training and Educating Your Team on Maintenance Practices

A. Importance of Skilled Maintenance Personnel

Having skilled maintenance personnel is crucial for preventing maintenance-related issues. Proper training ensures that your team understands and follows best practices for maintaining pump and dredge equipment. This training should cover both routine maintenance activities and how to address more complex issues that may arise. Educating your team on effective maintenance practices is key to the long-term success of your operations.

B. Ongoing Education and Updates on Equipment Maintenance

Maintenance practices and technologies are constantly evolving. It’s important to keep your team updated on new maintenance techniques and equipment. Providing resources for continuous learning and improvement ensures that your team stays current with the latest advancements, which can lead to more effective maintenance and better equipment performance.

VII. Conclusion

Regular maintenance is essential for the longevity and efficiency of pump and dredge equipment. By implementing the maintenance practices outlined in this article—such as routine inspections, lubrication, and component monitoring—you can prevent breakdowns, reduce downtime, and extend the life of your equipment. Proper training and the use of structured maintenance schedules further enhance the effectiveness of these practices. Investing in maintenance not only protects your equipment but also ensures that your operations run smoothly and efficiently for years to come.