Flooded Suction Centrifugal Slurry Pumps

Efficient Fluid Transfer with Flooded Suction Solutions

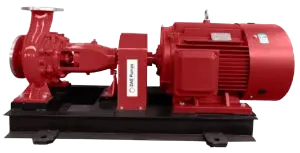

Flooded suction pumps, available in vertical and horizontal configurations, are essential for moving slurry and liquid between tanks, hoppers, and other storage systems. These pumps are installed externally and positioned towards the bottom or beneath the liquid level to leverage gravity, ensuring they remain consistently primed. Priming is crucial for efficient operation; with the chamber and piping always filled with water, these pumps allow quick and easy starts and stops. The horizontal style is more common due to its ease of maintenance, while the vertical design is preferred in space-limited environments.

DAE Pumps, a renowned leader in the pump and dredge industry, particularly in challenging environments like England, is your trusted partner. We specialize in designing and engineering robust vertical and horizontal flooded suction pumps with non-clog impellers. Our pumps are built to exceed the highest industry standards for reliability and durability, instilling confidence in our customers. These premium-quality pumps are offered at competitive prices. Contact us today for expert assistance in selecting the perfect pump solution for your needs!

Versatile Applications of Flooded Suction Pumps

Flooded suction pumps, the versatile workhorses of various industrial applications, are vital in sectors such as agriculture, oil and gas, sand and gravel pumping, and mining. Unlike submersible pumps, which operate submerged in liquid, flood suction pumps are positioned outside the liquid. These gravity-fed systems do not require a vacuum pump for priming, simplifying their setup and maintenance. Their adaptability makes them a reliable choice for your diverse needs.

Typically paired with an electric motor, flooded suction pumps achieve optimal control over startup speeds and operational parameters like flow and pressure through the use of a Variable Frequency Drive (VFD). A VFD is a type of motor controller that drives an electric motor by varying the frequency and voltage supplied to the motor. This technology allows for precise control of the pump’s performance, ensuring efficient operation and reducing energy consumption. While less common, diesel-driven motors are available for environments where electric power is not feasible. To ensure continuous operation, it’s crucial that liquid consistently feeds into the system; thicker materials might require a self-priming pump or vacuum pump to aid in liquid movement. DAE Pumps offers a range of self-priming pumps, providing reliable solutions for all pumping needs.

Comprehensive Guide to DAE Pumps' Flooded Suction Pump Series

Discover DAE Pumps’ extensive range of flooded suction pumps, a comprehensive guide that caters to diverse industrial needs. We are committed to providing you with the most detailed information and guidance, ensuring you make an informed decision for your pumping requirements.

Pump and Dredge Solutions

H-Series Slurry Suction Pumps

DAE Pumps’ H-Series Flooded Suction Horizontal Pumps excel in transferring slurry and liquid from storage units like tanks and hoppers, with flow rates up to 16,000 GPM. Available in various sizes, these pumps feature intakes ranging from 1.5 to 14 inches and discharges between 1 and 12 inches. Equipped with non-clogging impellers, they can pass solids up to 3.5 inches, ensuring they remain primed and ready for immediate operation.

Constructed from durable 27% Chrome White Iron, a high-chromium alloy known for its exceptional wear resistance and toughness, the H-Series pumps are designed for heavy-duty applications across mining and wastewater management industries. With metal or rubber liners and high-head configuration options, these pumps are customizable to meet specific operational needs while minimizing downtime and enhancing productivity.

Pump and Dredge Solutions

V-Series Flooded Suction Pumps

DAE Pumps’ V-Series Flooded Suction Vertical Pumps are high-performance centrifugal pumps that efficiently handle slurry and liquid from tanks and hoppers. With the capacity to manage flow rates up to 18,000 GPM, these pumps stand vertically, making them ideal for confined spaces with limited installation areas. The V-Series comes in various sizes, featuring intakes from 3 to 14 inches and discharges from 2 to 12 inches. Their ability to pass solids up to 3.5 inches and the advantage of being pre-primed ensures that these pumps are operationally ready right from the start.

Suited for a range of applications, including municipal work, wastewater management, agriculture, and dewatering, the V-Series pumps minimize downtime and boost productivity through their robust, non-clog impellers. DAE Pumps offers these pumps in multiple configurations and materials, such as ductile iron, hi-chrome, stainless steel, and duplex stainless, perfectly matching specific pumping needs. When choosing a V-Series pump, consider factors like material type, fluid viscosity, pumping distance, desired GPM, and other specific requirements to ensure optimal capacity, head, efficiency, power, and speed performance.

Pump and Dredge Solutions

SPW-Series Flooded Suction Pumps

The SPW-Series from DAE Pumps showcases robust centrifugal pumps that efficiently transfer slurry and liquid from tanks and hoppers using gravity. These pumps are capable of handling impressive flow rates up to 16,000 GPM. This series includes a range of pump sizes with intakes from 1.5 to 14 inches and discharges from 1 to 12 inches, ideal for various industrial requirements. Featuring non-clogging impellers, the SPW-Series pumps can pass solids up to 3.5 inches and are primed for immediate operation, simplifying the startup process.

Built for heavy-duty applications, the SPW-Series pumps are designed to minimize operational downtime and enhance productivity by smoothly pumping solids. These pumps are constructed from durable 27% Chrome White Iron, ensuring long-term reliability and performance. Available with metal or rubber liners and high head options, the SPW-Series can be tailored to meet specific needs in diverse mining, wastewater, and construction settings. When selecting these pumps, it’s crucial to consider factors like the material type, fluid viscosity, pumping distance, desired GPM, and other project-specific details to ensure the pump’s capacity, head, efficiency, power, and speed meet your requirements.

Pump and Dredge Solutions

Our Brands

Related Equipment

Dewatering Pumps

Explore our comprehensive selection of dewatering pumps designed for diverse applications across England, including irrigation, fountains, and liquid transfer tasks. Recognized for their exceptional performance, our pumps offer reliability and profitability, ensuring efficiency in every operation they handle.

Are you seeking top-notch pump and dredge equipment for your industrial needs?

Or Mail us today sales@pumpanddredgesolutions.com