Submersible slurry pumps play a crucial role in industries that handle challenging fluids, including mining, dredging, and wastewater treatment. These pumps are designed to operate efficiently in harsh environments, where traditional pumps might fail. Their ability to operate fully submerged in slurry or wastewater makes them indispensable for many industrial operations.

Industrial submersible pumps are engineered to handle high-volume, abrasive, and corrosive fluids, ensuring that even the most difficult materials can be moved with minimal risk of clogging or damage. These pumps are essential for industries such as mining, where thick slurries containing sand, gravel, and chemicals must be pumped continuously over long distances.

For more demanding applications, a heavy-duty submersible slurry pump offers enhanced durability, capable of handling the toughest conditions. These pumps are constructed with specialized materials that resist wear and corrosion, enabling them to handle large amounts of abrasive solids without compromising performance. They are particularly useful in high-intensity operations where reliability and longevity are crucial for maintaining productivity and minimizing downtime.

In this blog, we’ll explore how submersible slurry pump technology is enhancing operational efficiency in harsh environments, offering solutions that improve performance and reduce maintenance costs across various industries.

Understanding Submersible Slurry Pumps

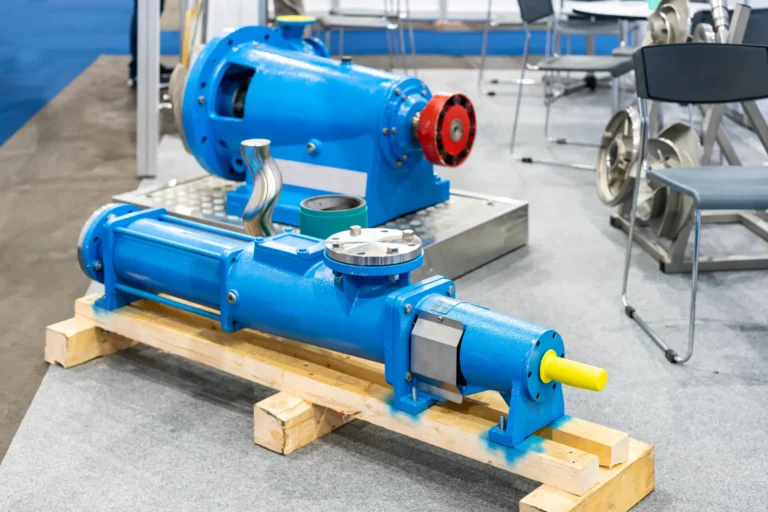

Submersible slurry pumps are specially designed pumps that are fully submerged in the fluid they are pumping, typically in applications involving the handling of slurries containing abrasive materials, such as sand, mud, or chemicals. These pumps are built to operate efficiently in harsh environments, where the material being pumped is thick, corrosive, or has a high concentration of solids. The unique design of submersible slurry pumps enables them to be placed directly into the fluid, eliminating the need for priming systems. This makes them highly effective and efficient for continuous operation.

An industrial submersible pump is specifically designed for high-volume and high-pressure applications, ensuring that heavy-duty fluid transfer tasks are handled with ease. These pumps are utilized across various industries, including mining, dredging, and wastewater treatment, where large quantities of material need to be pumped over extended periods. The industrial submersible pump is engineered to handle challenging conditions, including high solid content, corrosive elements, and abrasive substances.

For more demanding conditions, a heavy-duty submersible slurry pump is required. These pumps are constructed with reinforced components, including wear-resistant materials, to withstand the most abrasive and aggressive slurries, offering enhanced durability and longer operational lifespans. They are ideal for heavy-duty operations where reliability and performance are essential.

How Submersible Slurry Pumps Work

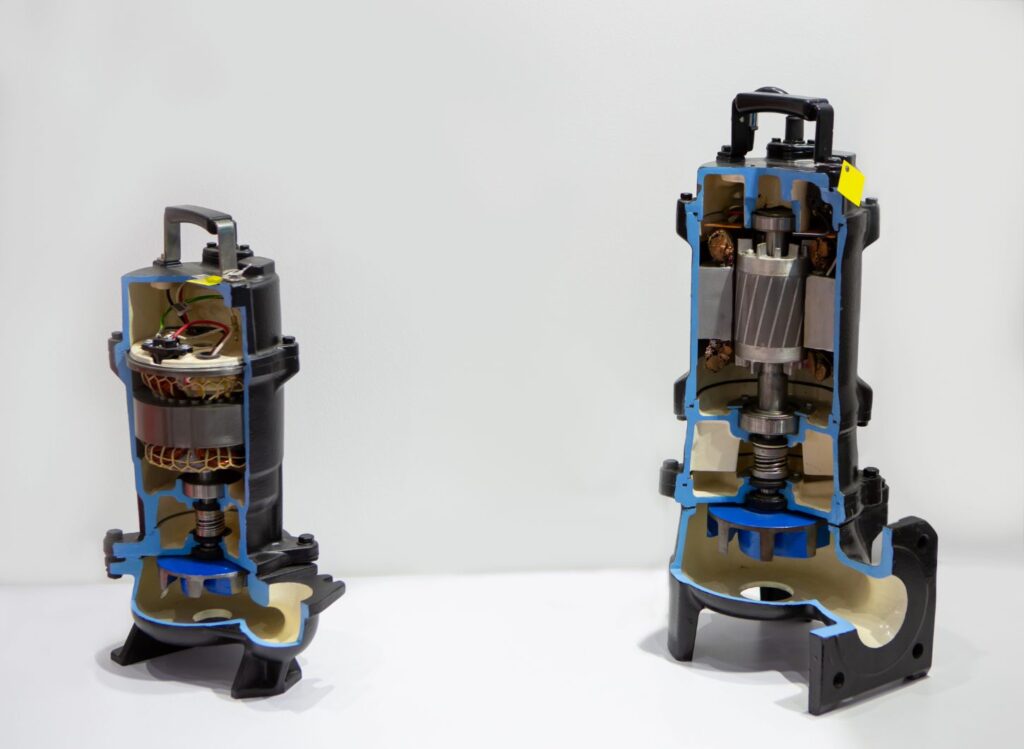

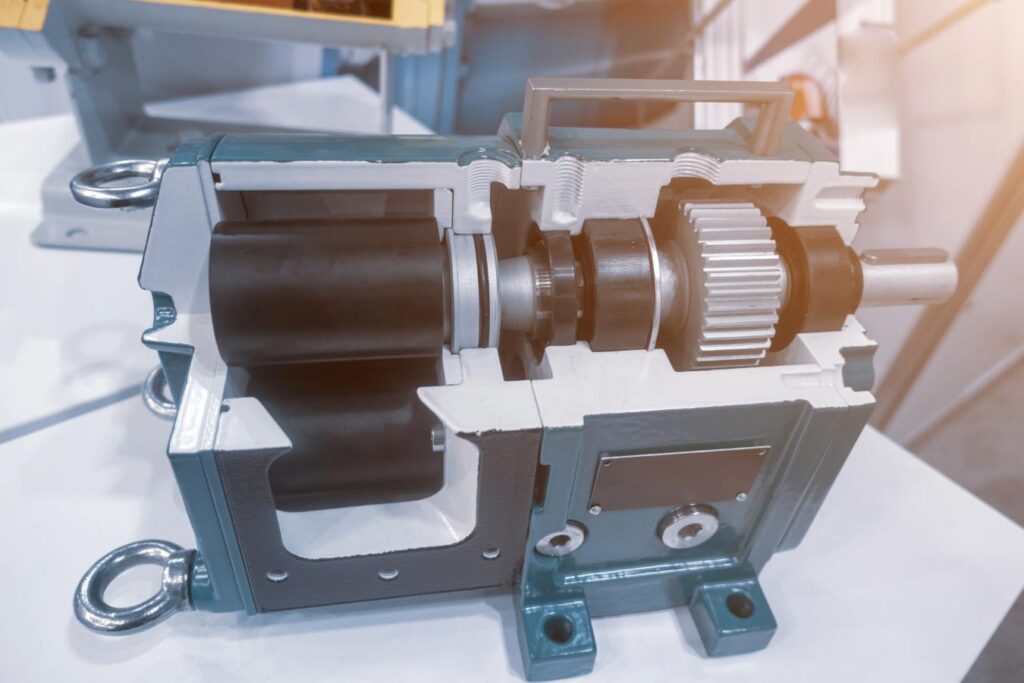

Submersible slurry pumps are designed to operate while fully submerged in liquids, making them ideal for handling abrasive slurries, thick mud, and other high-solid mixtures. These pumps operate by utilizing an electric motor housed in a sealed casing that is directly connected to the pump impeller. The motor drives the impeller, which creates a vacuum that draws the slurry into the pump and expels it through the discharge pipe. The pump’s submersible design reduces cavitation risks and eliminates the need for priming, allowing it to work efficiently in confined spaces or submerged environments.

Industrial submersible pumps are typically constructed with stronger materials and components to withstand the demanding requirements of industrial applications. They are often made from corrosion-resistant alloys and feature specialized seals to prevent damage from harsh, abrasive materials. The motor and impeller are designed for durability, allowing the pump to work continuously without overheating or wearing out.

For more demanding applications, a heavy-duty submersible slurry pump is used. These pumps are built with even more robust materials, offering higher solid-handling capacities and enhanced durability in extreme environments. Whether handling mining tailings, dredging, or industrial wastewater, submersible slurry pumps ensure that operations run smoothly and efficiently, even under the most challenging conditions.

Heavy Duty Submersible Slurry Pumps: Specialized for Extreme Conditions

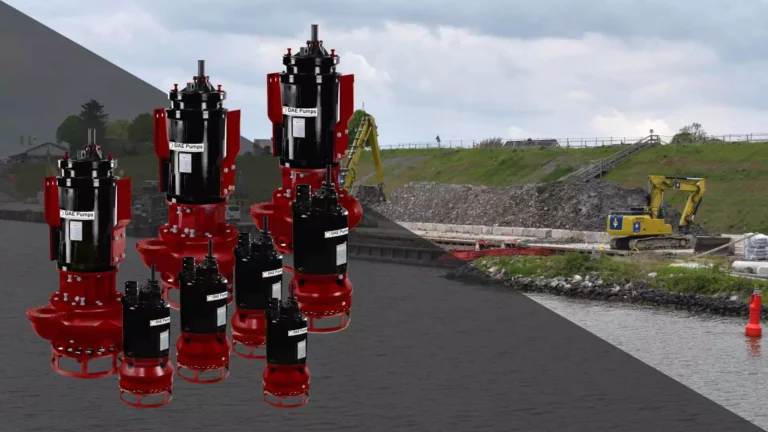

Heavy-duty submersible slurry pumps are specifically designed to tackle the most demanding conditions in industrial applications. Unlike standard pumps, these pumps are designed to handle highly abrasive, viscous, and corrosive materials commonly found in industries such as mining, dredging, and wastewater treatment. These environments require pumps that can withstand high pressure, extreme temperatures, and constant exposure to harsh chemicals or solids.

The primary feature that distinguishes heavy-duty submersible slurry pumps is their robust construction. These pumps are made with specialized materials, such as high-chrome alloys and ceramic coatings, to resist wear and tear caused by the abrasive slurry they handle. Their design features reinforced seals and motor protection systems to prevent damage from the harsh conditions in which they operate.

Industrial submersible pumps, including the heavy-duty models, offer several advantages in these extreme environments. They are submersible, meaning they can operate directly within the slurry, reducing cavitation risks and ensuring efficient fluid transfer without the need for external priming systems. Additionally, these pumps are designed for continuous and reliable operation, making them ideal for projects that require round-the-clock functionality.

Whether in heavy industrial processes or harsh environmental conditions, a heavy-duty submersible slurry pump provides the reliability and performance necessary to maintain operations and reduce maintenance costs in demanding applications.

Technological Advancements in Submersible Slurry Pumps

Technological advancements in submersible slurry pumps have significantly enhanced their performance, efficiency, and reliability in harsh environments. Over the years, these innovations have enabled pumps to handle more challenging materials, increase their lifespan, and reduce the need for frequent maintenance. One of the key developments has been the use of advanced materials, such as high-chrome alloys and ceramic coatings, which enhance the durability of the pump’s components, particularly when handling abrasive slurries. These improvements are particularly beneficial in industries like mining, dredging, and wastewater treatment.

Another major advancement is the integration of smart technology into submersible slurry pumps. Features such as real-time monitoring, IoT connectivity, and digital sensors enable the continuous tracking of pump performance. This enables predictive maintenance, reducing downtime and extending the pump’s service life. Industrial submersible pumps are increasingly being designed with energy-efficient motors that optimize power usage and reduce operational costs, making them more sustainable for long-term use.

Heavy-duty submersible slurry pumps have also seen improvements in their ability to manage larger volumes and more abrasive materials. With better sealing systems, wear-resistant impellers, and robust construction, these pumps are now capable of tackling the most demanding applications, ensuring consistent and reliable operation in the harshest conditions.

Challenges in Harsh Environments and How Submersible Slurry Pumps Overcome Them

Operating in harsh environments presents several challenges that must be addressed to ensure optimal pump performance. One of the primary difficulties faced by submersible slurry pumps is handling abrasive materials. Slurries often contain sand, gravel, or other hard particles that can rapidly wear down the pump’s internal components. Submersible slurry pumps are designed with robust materials, such as high-chrome alloys and wear-resistant coatings, to withstand the abrasive nature of these materials, ensuring long-term durability and efficiency.

In addition to abrasion, the high temperatures and corrosive environments found in industries like mining and wastewater management can cause significant damage to pumps over time. Industrial submersible pumps are designed to withstand these extreme conditions with specially engineered seals, corrosion-resistant materials, and advanced motor protection systems. These features help extend the pump’s life while maintaining reliable operation under challenging conditions.

For more demanding applications, such as dredging or mining, a heavy-duty submersible slurry pump is essential. These pumps are specifically engineered to handle large volumes of thick, highly abrasive slurry, offering greater durability and performance compared to standard models. By addressing these challenges, submersible slurry pumps allow industries to continue operations efficiently, reducing downtime and maintenance costs while improving overall productivity.

Selecting the Right Submersible Slurry Pump for Your Application

Selecting the right submersible slurry pump for your application is crucial to ensuring optimal performance, longevity, and efficiency. Several factors should be considered when selecting a pump, including the characteristics of the slurry, the required flow rate, and the specific operating conditions.

First, it is important to evaluate the nature of the slurry you are handling. Consider the size, density, and abrasiveness of the solids in the slurry. For heavier, more abrasive materials, a heavy-duty submersible slurry pump is necessary. These pumps are designed to withstand the wear and tear from large particles and harsh environments, offering enhanced durability and longer service life.

Next, determine the required flow rate and head height for your operation. Industrial submersible pumps come in a wide range of capacities and sizes, so it’s essential to match the pump’s specifications to your operational needs. Choosing the right size ensures that the pump can efficiently move the required volume of slurry without causing unnecessary wear or energy consumption.

In addition, consider the pump’s material construction. Pumps made from high-chrome alloys or other corrosion-resistant materials are ideal for handling aggressive slurries in industries like mining or wastewater treatment.

Finally, think about maintenance and support. Reliable manufacturers of submersible slurry pumps will provide technical support, warranty coverage, and easy access to replacement parts, ensuring that your investment is protected and your pump performs efficiently for years to come.

Submersible Slurry Pump Technology in Action

Case studies showcasing the real-world applications of submersible slurry pumps highlight the significant advantages these pumps offer in harsh and demanding environments. One such example is in the mining industry, where submersible slurry pumps are used to handle abrasive tailings and high-solid slurry. Mining operations often deal with thick, heavy slurries, which can be incredibly abrasive to standard pumps. However, by using submersible slurry pumps, operators can efficiently transport these materials without worrying about clogging or excessive wear. In cases where the slurry is particularly dense, a heavy-duty submersible slurry pump is essential, as it is specifically designed to handle the highest solid content and most extreme conditions.

Another example is in dredging operations, where industrial submersible pumps are used to maintain efficient operation in water bodies with varying sediment and sludge concentrations. In harbors, rivers, and lakes, dredging helps maintain proper water flow for navigation, and submersible slurry pumps play a crucial role in managing the removal of sediments. Their ability to operate submerged ensures that the pumping process is smooth, reducing the need for additional equipment.

Ultimately, in wastewater treatment plants, submersible slurry pumps play a crucial role in removing thick sludge and solids from water systems. These pumps ensure that the treatment process runs continuously without clogging, improving efficiency and minimizing maintenance costs.

These case studies demonstrate the versatility and importance of submersible slurry pumps across various industries, highlighting their value in enhancing productivity, efficiency, and operational sustainability.

The Future of Submersible Slurry Pump Technology

The future of submersible slurry pump technology is shaped by ongoing innovations aimed at improving efficiency, durability, and adaptability in harsh environments. As industries such as mining, dredging, and wastewater management continue to evolve, the demand for pumps that can handle increasingly extreme conditions, larger volumes of solids, and more complex slurry mixtures is growing. Submersible slurry pumps are set to become even more advanced, with new materials and designs focused on extending their lifespan and reducing maintenance costs.

One major trend is the integration of digital technologies into industrial submersible pumps. IoT-enabled sensors and monitoring systems are being increasingly incorporated into these pumps, enabling real-time performance tracking, predictive maintenance, and enhanced operational control. These technologies help reduce downtime, prevent costly breakdowns, and optimize the overall efficiency of pumping systems. As a result, industrial submersible pumps will become even more reliable and smarter, with the ability to alert operators about wear and potential issues before they become critical.

Another promising development is the focus on energy efficiency. The future of heavy-duty submersible slurry pumps will likely see the introduction of more energy-efficient designs that consume less power while maintaining high performance. These innovations will not only reduce operational costs but also help businesses meet growing environmental regulations focused on sustainability and energy conservation.

Conclusion

In conclusion, submersible slurry pumps are indispensable tools in various industries, providing unmatched efficiency and reliability in demanding environments. These pumps have revolutionized the handling of abrasive slurries, thick liquids, and solids-laden fluids across various sectors, including mining, dredging, and wastewater treatment. By operating fully submerged, submersible slurry pumps minimize the risk of cavitation and deliver consistent performance, ensuring smooth operations even in challenging conditions.

The advancements in industrial submersible pumps have made them a cornerstone of industrial processes, delivering high flow rates and robust performance even in demanding settings. With innovations in materials, design, and technology, these pumps are now more efficient, durable, and energy-saving than ever before. Whether it’s for large-scale industrial projects or specialized operations, industrial submersible pumps ensure maximum uptime and reduced maintenance costs, which are essential for any business looking to maintain productivity.

For extreme environments that require handling large volumes of thick, abrasive slurries, the heavy-duty submersible slurry pump is the ideal solution. Designed for the toughest conditions, these pumps offer superior resistance to wear and corrosion, ensuring they can handle the most demanding applications without compromising on performance.