Selecting the right submersible slurry pump is crucial for ensuring project efficiency, cost-effectiveness, and durability. Whether you’re dealing with mining operations, dredging activities, or industrial processes, the correct choice can significantly impact the performance of your operation. However, the process of submersible slurry pump selection can be challenging, given the variety of options available and the specific demands of different applications.

This guide will help you navigate these challenges, providing insights into factors to consider, tips for finding the best slurry pump, and advice on long-term maintenance. By understanding your pump for project needs, you can make informed decisions and maximize your project’s success.

Understanding Submersible Slurry Pumps

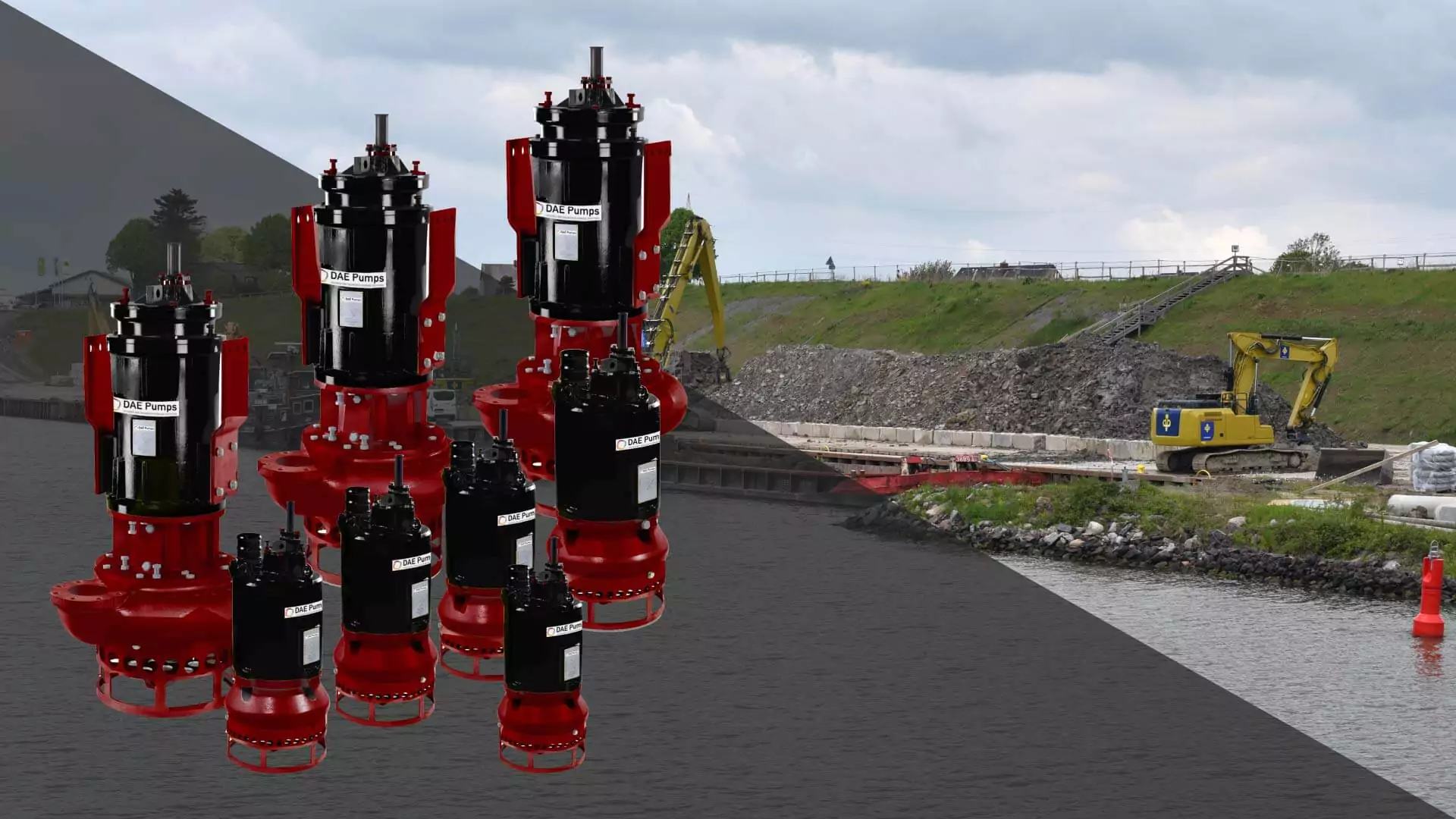

A submersible slurry pump is designed to handle solids-laden liquids and operate underwater. These pumps are highly effective in harsh conditions, making them essential for projects in mining, dredging, construction, and various industrial applications.

The key to effective submersible slurry pump selection lies in understanding how these pumps work and their specific applications. For example:

- Mining: Used to transport abrasive slurry containing minerals and other particulates.

- Dredging: Essential for moving sediments and debris in marine or river environments.

- Construction: Assists in dewatering and material handling tasks.

- Industrial Projects: Handles wastewater and slurry mixtures in manufacturing or chemical industries.

To find the right pump for project needs, it’s critical to assess the type of slurry being handled, operating conditions, and the pump’s capabilities. Without this understanding, it becomes difficult to make a selection that aligns with your project’s requirements. Submersible slurry pump selection starts with knowing your application’s unique demands.

Key Factors in Submersible Slurry Pump Selection

Making the right submersible slurry pump selection requires careful evaluation of multiple factors. Below are the most critical considerations:

Material Compatibility

The slurry can vary greatly in its composition, ranging from fine particles to highly abrasive or corrosive mixtures. Choosing the best slurry pump involves ensuring that the pump materials can withstand these harsh conditions:

- Abrasive Slurries: Require wear-resistant materials such as high-chrome alloys.

- Corrosive Slurries: May necessitate corrosion-resistant coatings or stainless steel components.

- Viscous Slurries: Benefit from pumps with strong impeller designs to maintain a consistent flow.

Understanding the material compatibility ensures your pump will operate efficiently without frequent breakdowns. Material compatibility is a key consideration in submersible slurry pump selection because it directly affects the pump’s durability.

Flow Rate and Head Requirements

Every project has specific flow and pressure needs. To meet these demands:

- Calculate the required flow rate (volume of slurry to be transported per unit of time).

- Determine the head requirements, which is the vertical distance the slurry needs to be pumped.

Matching the pump’s capabilities with your project’s operational parameters is a cornerstone of effective submersible slurry pump selection.

Power and Energy Efficiency

Submersible slurry pumps are powered either electrically or hydraulically. Each option has its advantages:

- Electric Pumps: Ideal for consistent, long-term operations and lower energy costs.

- Hydraulic Pumps: Better suited for high-power applications and remote locations.

Evaluate the energy consumption of each model to ensure cost-effectiveness without compromising performance. This aspect of submersible slurry pump selection not only ensures efficiency but also contributes to lower operational costs.

Choosing the Best Slurry Pump for Specific Applications

Identifying the best slurry pump involves tailoring your choice to the specific needs of your project. Here’s how to make the right decision:

- Heavy-Duty Applications: High-performance pumps with enhanced wear resistance and power capacity are ideal for mining and large-scale dredging projects.

- Light-Duty Applications: For smaller projects, cost-efficient pumps can handle less abrasive or less demanding slurries effectively.

- Customization: Some manufacturers offer customizable options to meet unique project requirements, such as specialized impellers or coatings.

Comparing features such as durability, efficiency, and material quality across different models will help you find the best slurry pump. Additionally, using a slurry pump guide or consulting with experts can clarify the options available. Customization is often a game-changer in submersible slurry pump selection for unique or challenging project conditions.

Tips for Selecting the Right Pump for Project Needs

To refine your submersible slurry pump selection further, consider the following tips:

- Evaluate Long-Term Costs: Beyond the initial purchase price, consider operational costs like maintenance, pump parts replacement, and energy consumption. A slightly higher upfront investment may save significant costs in the long run.

- Brand Reputation and Reviews: Opt for reputable brands known for producing high-quality slurry pumps. Customer reviews and testimonials can offer valuable insights.

- Expert Consultation: Consult with pump suppliers or industry professionals for tailored advice. Their experience can help you identify the right pump for project needs.

These tips ensure you make an informed choice, aligning your selection with both your immediate project demands and long-term operational goals. When considering submersible slurry pump selection, always weigh the pros and cons of each option carefully.

Slurry Pump Guide for Maintenance and Performance

Even the best slurry pump requires regular maintenance to ensure longevity and consistent performance. A slurry pump guide for maintenance should include:

- Routine Inspections: Regularly check for wear and tear on impellers, seals, and casings.

- Scheduled Cleaning: Prevent sediment buildup by cleaning the pump after heavy usage.

- Timely Parts Replacement: Replace worn-out components promptly to avoid performance issues.

Using tools and software to track performance and schedule maintenance can further enhance efficiency. By following a slurry pump guide, you can extend the lifespan of your equipment and minimize downtime. Proper maintenance is a natural extension of submersible slurry pump selection, as the right choice simplifies upkeep.

Conclusion

Choosing the right submersible slurry pump is an investment in your project’s success. By understanding the fundamentals of submersible slurry pump selection, considering factors like material compatibility and flow rate, and using a slurry pump guide for maintenance, you can ensure your equipment operates at peak efficiency.

The right pump for project needs not only enhances productivity but also reduces long-term costs, saving you time and resources. Take the time to evaluate your options, consult with experts, and make an informed decision. Start your journey toward successful projects with the best slurry pump tailored to your unique requirements. Thoughtful submersible slurry pump selection is the foundation of reliable and efficient operations.