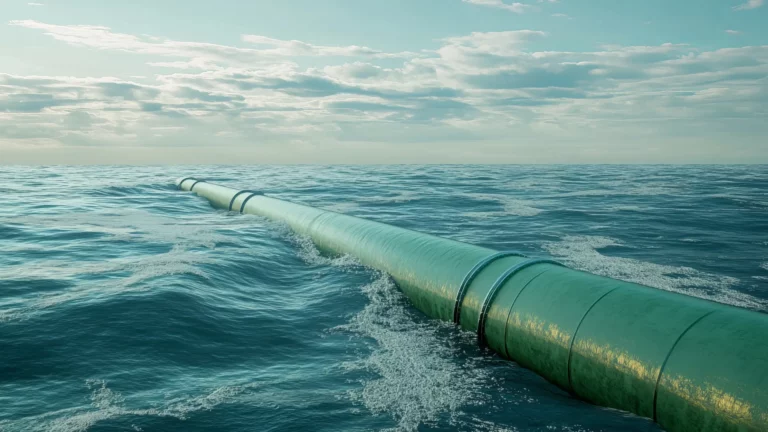

Maintaining pipeline integrity is essential in any dredging operation. Pipelines are the lifeline that transports slurry, sediments, and other materials, ensuring efficient and continuous flow from one point to another. However, these pipelines face several challenges, including harsh environmental conditions, abrasion, and the constant pressure of material flow. To prevent damage and ensure the pipeline remains functional, it is crucial to incorporate solutions that can enhance stability, buoyancy, and overall durability.

One such solution is the use of dredge pipeline floats. These floats play a pivotal role in supporting pipeline systems by keeping them buoyant and aligned, preventing them from sinking or experiencing undue strain. By incorporating high-quality dredging pipeline floats, dredging companies can maintain pipeline integrity, ensuring smooth operations and reducing the risk of costly repairs or downtime.

In this article, we will explore how dredge pipeline floats contribute to pipeline durability, the mechanics behind their functionality, and the numerous benefits of investing in high-quality floats for dredging operations.

The Role of Dredge Pipeline Floats

What Are Dredge Pipeline Floats?

Dredge pipeline floats are buoyant devices attached to pipelines used in dredging operations. Their primary function is to keep the pipeline afloat, preventing it from sinking into the seabed or being damaged by abrasive surfaces and debris. These floats are typically made from durable materials such as polyethylene or high-density foam, which provides the buoyancy and protection needed in harsh marine environments.

Dredging pipeline floats ensures that the pipeline remains suspended in water, making it easier to transport materials from one location to another. Without these floats, pipelines would be more susceptible to damage from the seabed or water pressure, which could compromise their structural integrity.

How They Work

The mechanics behind dredge pipeline floats are simple yet highly effective. Floats are strategically placed along the length of the pipeline at regular intervals. This consistent spacing allows the floats to distribute the weight of the pipeline evenly, ensuring that it stays afloat and maintains its alignment.

The buoyancy provided by the floats ensures that the pipeline does not sink, even when fully loaded with heavy materials. The floats also prevent the pipeline from bending or sagging, which could lead to misalignment and increased wear. By providing support and stability, dredge floats help the pipeline perform optimally throughout the dredging operation.

Importance in Pipeline Integrity

Pipeline stability is crucial for ensuring that the materials being transported reach their destination without disruption. Dredging operations often take place in challenging environments where pipelines are exposed to constant stress from water currents, sediment buildup, and the weight of the materials being moved. Without proper support, pipelines can experience strain, leading to cracks, leaks, or complete failure.

Dredge pipeline floats contribute significantly to maintaining the integrity of the pipeline system. By keeping the pipeline buoyant and aligned, the floats reduce the risk of damage, ensuring the pipeline remains functional for extended periods. Their role in stabilizing the pipeline directly impacts the overall success of dredging operations, making them a critical component in protecting pipeline strength.

Maintaining Stability and Buoyancy

Buoyancy in Rough Conditions

Dredging operations often take place in rough waters where maintaining pipeline stability can be particularly challenging. Dredge pipeline floats are designed to provide consistent buoyancy even in turbulent conditions. By keeping the pipeline afloat, these floats prevent it from sinking, which could lead to blockages, damage, or delays.

The ability to maintain buoyancy in rough conditions ensures that pipelines can operate efficiently without the risk of submersion or damage from contact with the seabed. This consistency is vital for ensuring smooth and uninterrupted material flow.

Preventing Misalignment

Pipeline alignment is essential for maintaining efficient operations. When pipelines are not properly aligned, material flow can become disrupted, leading to blockages or uneven distribution of pressure along the pipeline. Misalignment also increases the likelihood of damage, as certain sections of the pipeline may be subjected to more stress than others.

Dredging pipeline floats play a key role in preventing misalignment by providing stable support along the length of the pipeline. By keeping the pipeline properly positioned, the floats reduce the risk of bending or sagging, ensuring that materials are transported smoothly and efficiently.

Reducing Physical Stress

Pipelines are constantly subjected to physical stress during dredging operations. The weight of the materials being transported, combined with environmental factors such as water currents and debris, can place significant strain on the pipeline. Without adequate support, this stress can lead to cracks, leaks, or even complete failure of the pipeline system.

Dredge floats help reduce physical stress by evenly distributing the weight of the pipeline and the materials it carries. This even distribution minimizes the strain on any one section of the pipeline, reducing wear and tear over time. By stabilizing the pipeline and preventing excessive stress, dredge pipeline floats extend the operational life of the pipeline system.

Benefits of Using High-Quality Dredge Pipeline Floats

Enhanced Pipeline Integrity

One of the most significant benefits of using high-quality dredge floats is the enhancement of pipeline integrity. Premium floats are designed to provide reliable buoyancy and protection, ensuring that pipelines remain stable and functional throughout the operation. By maintaining pipeline alignment and reducing the risk of damage, these floats help extend the life of the pipeline and reduce the need for frequent repairs or replacements.

Cost-Effectiveness

Investing in high-quality dredge pipeline floats may come with a higher initial cost, but the long-term savings far outweigh the upfront expense. High-quality floats reduce the frequency of repairs and maintenance, leading to fewer operational disruptions. The durability of premium floats ensures that pipelines remain functional for longer periods, reducing the need for costly replacements and downtime.

By reducing the risk of damage and maintaining pipeline efficiency, high-quality dredge floats contribute to the overall cost-effectiveness of dredging operations.

Improved Operational Efficiency

Dredge floats also play a key role in improving operational efficiency. Stable pipelines supported by reliable floats ensure smooth material flow, reducing the likelihood of blockages or interruptions. This increased efficiency helps dredging companies complete projects on time and within budget, leading to higher productivity and profitability.

With fewer operational disruptions and enhanced pipeline performance, high-quality floats enable dredging companies to maintain consistent progress throughout their operations.

Conclusion

Dredge pipeline floats are a critical component of maintaining pipeline integrity in dredging operations. By providing buoyancy, stability, and protection, these floats ensure that pipelines remain functional and aligned throughout the operation, reducing the risk of damage and minimizing operational disruptions. The benefits of using high-quality dredge floats are clear: they enhance pipeline integrity, improve operational efficiency, and contribute to long-term cost savings.

Investing in premium dredge pipeline floats is essential for any dredging company looking to protect its pipeline systems and ensure the success of its operations. By prioritizing high-quality floats, companies can safeguard their pipelines, reduce maintenance needs, and ensure smoother, more efficient dredging operations.